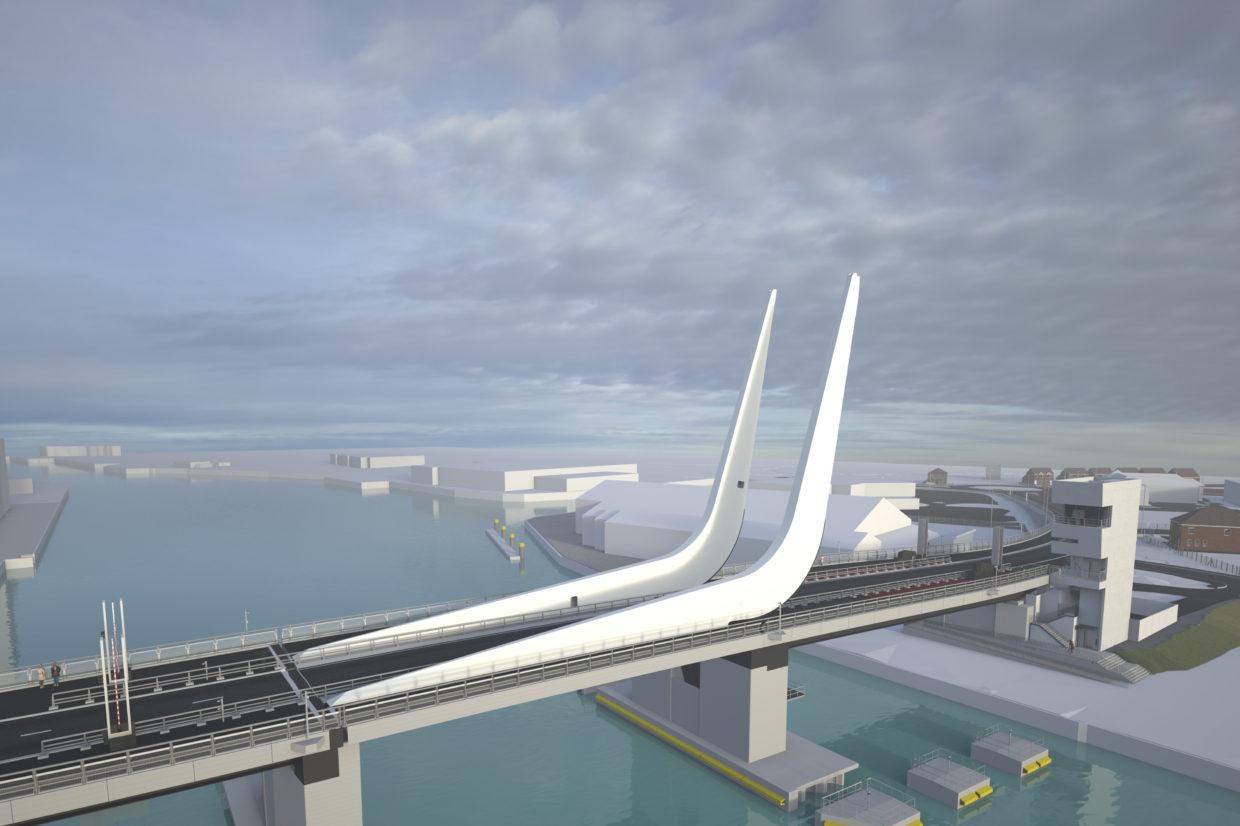

When complete the new Gull Wing Bridge in Lowestoft will offer the third crossing over Lake Lothing. The bridge and associated works will have been one of Suffolk's most significant infrastructure developments in recent years.

The main function of the bridge is to provide better movement of traffic around Lowestoft by improving connections between the north and south sides of the town. The project is also expected to deliver secondary economic benefits to local business and attract more trade into the area.

Farrans were appointed as main contractor by Suffolk County Council and started work on the project in Spring 2021.

Due to the nature of the ground in this area, each support for the new bridge required deep piled foundations to be installed to be able to accommodate the high loads generated by the structure.

P J Edwards were appointed by Farrans to install the deep land based piled foundations on the project which consisted of 145no. 1200mm dia. piles, drilled to depths up to 32m, and distributed over 2no. abutments and 5no. intermediate piers.

Ground Conditions

Ground conditions for the site were extremely challenging with softer alluvium and silt overlying the dense sands and gravels of the Crag Formation.

For these ground conditions, and diameter of pile required, the standard approach would normally be to adopt traditional rotary bored piles installed with the aid of drilling fluids such as bentonite or polymer.

Large Diameter Deep CFA Piles

This project provided excellent opportunity for P J Edwards to demonstrate again their ability to install large diameter deep CFA piles to limits beyond normal expectations.

The rig used for this work was the 130t Llamada P240 drilling rig which boasts 42Tm of available drilling torque combined with 17t of crowd force, and importantly 130t of extraction force.

In addition to this P J Edwards were able to work with the project scheme designers, Arup, and redetail pile reinforcement cages to allow installation of cages up to 21m long, delivered to site prefabricated in single lengths.

In summary, on this project P J Edwards offered a very cost effective alternative to traditional rotary piles giving the client the benefit of both cost and programme reduction.